Providing innovative services to power generation developers, owners, and operators, leveraging technical, financial, and operational expertise.

Cost-Effective Peak and Grid-Support Power

In partnership with a leading gas turbine OEM, WattStock provides refurbished gas turbine power generation units that combine significantly lower capital cost savings with a wrap-around OEM warranty. Our plants are supporting networks with growing diversified green energy sources and providing vital backup services to stressed grid operators.

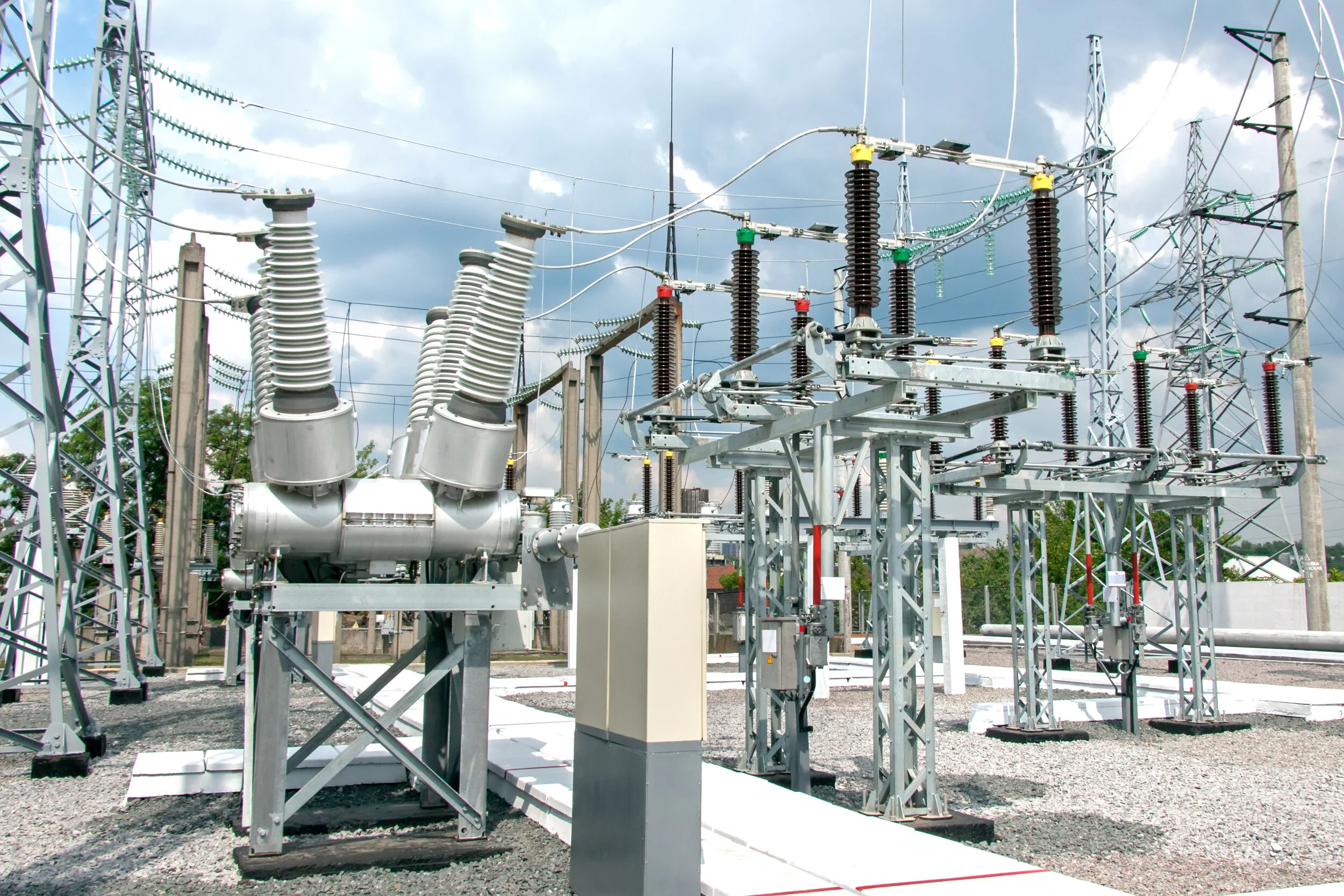

Improving Grid Resiliency

Until now, operators could choose between either buying and maintaining expensive spare transformers or waiting until one fails and then trying to find a replacement. With cycle times for replacing large power transformers running 9-18 months, lost revenue from a typical transformer failure may total tens of millions of dollars. WattStock’s Transformer Recovery Inventory Program “TRIP™” enables operators to avoid the large capital expense of buying, storing, and maintaining dedicated spares, while gaining guaranteed rights to temporary replacements from WattStock, utilizing WattStock’s revolutionary FLEX™ transformer design.

Providing Asset Knowledge

Evolving power markets and power technologies are creating opportunities for operators to dispose of used equipment and for developers to acquire and re-purpose used equipment. WattStock’s Advisory Services helps both Sellers and Buyers with valuations, market data, equipment inspections and reports, logistics, equipment availability and potential surplus equipment applications.